Synnor-engineering Your Large-Scale Electrical Enclosure Solutions

We go beyond standard manufacturing to deliver fully integrated enclosures—designed, built, and validated for both indoor and outdoor applications. Producing a wide range of electrical enclosures in varying sizes, configurations, materials, and protection ratings, we specialize in customizing every aspect to meet complex operational and spatial requirements. Tell us your application. We’ll deliver a complete enclosure solution!

GGD Type Enclosure

GGD-type enclosures are designed for superior flexibility and ease of installation. Their modular design and standardized mounting holes simplify component replacement or upgrades.

An effective natural cooling system is achieved through ventilation slots on the top and bottom of the cabinet, which promotes continuous airflow to dissipate heat.

The panels are finished with a high-quality powder coating, ensuring durability and a professional appearance.

XL-21 Type Enclosure

Customized Enclosure

Support custom any sizes and design of enclosure, with material from Stainless Steel, galvanized Steel to Mild Steel, surface treatment from Brushing to powder coating.

SYNNOR

Manufacturing Capacity

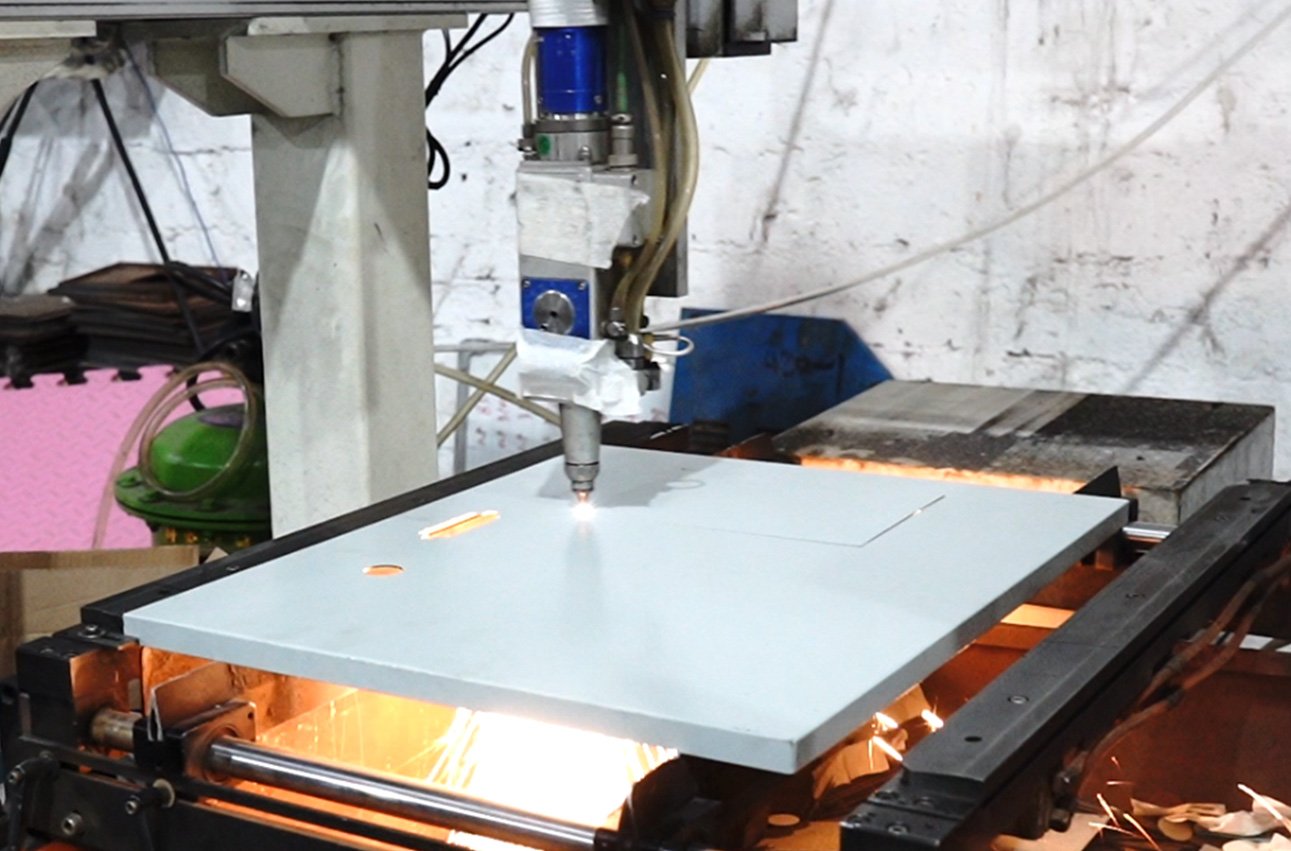

Electrical Enclosure Laser Cutting

±0.05mm precision with smooth, burr-free edges and scratch-free surfaces. High-performance laser cutting, simplified

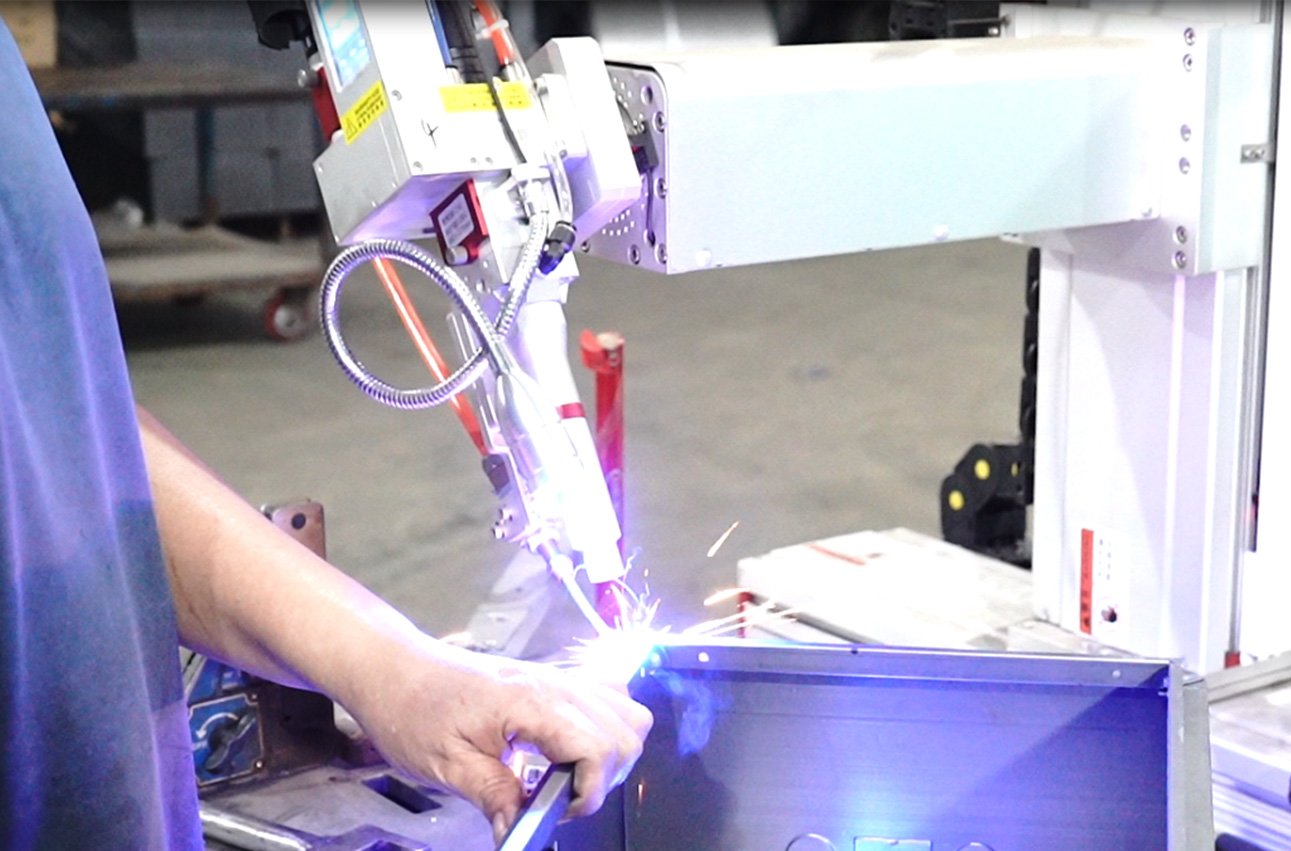

Electrical Enclosure Welding

Argon Arc Welding delivers cleaner, stronger, and higher quality welds and it prevents oxidation for flawless results on metals like stainless steel

Electrical Enclosure Bending

Professional bending machine makes bending accuracy ± 0.5mm, even different designs of junction box

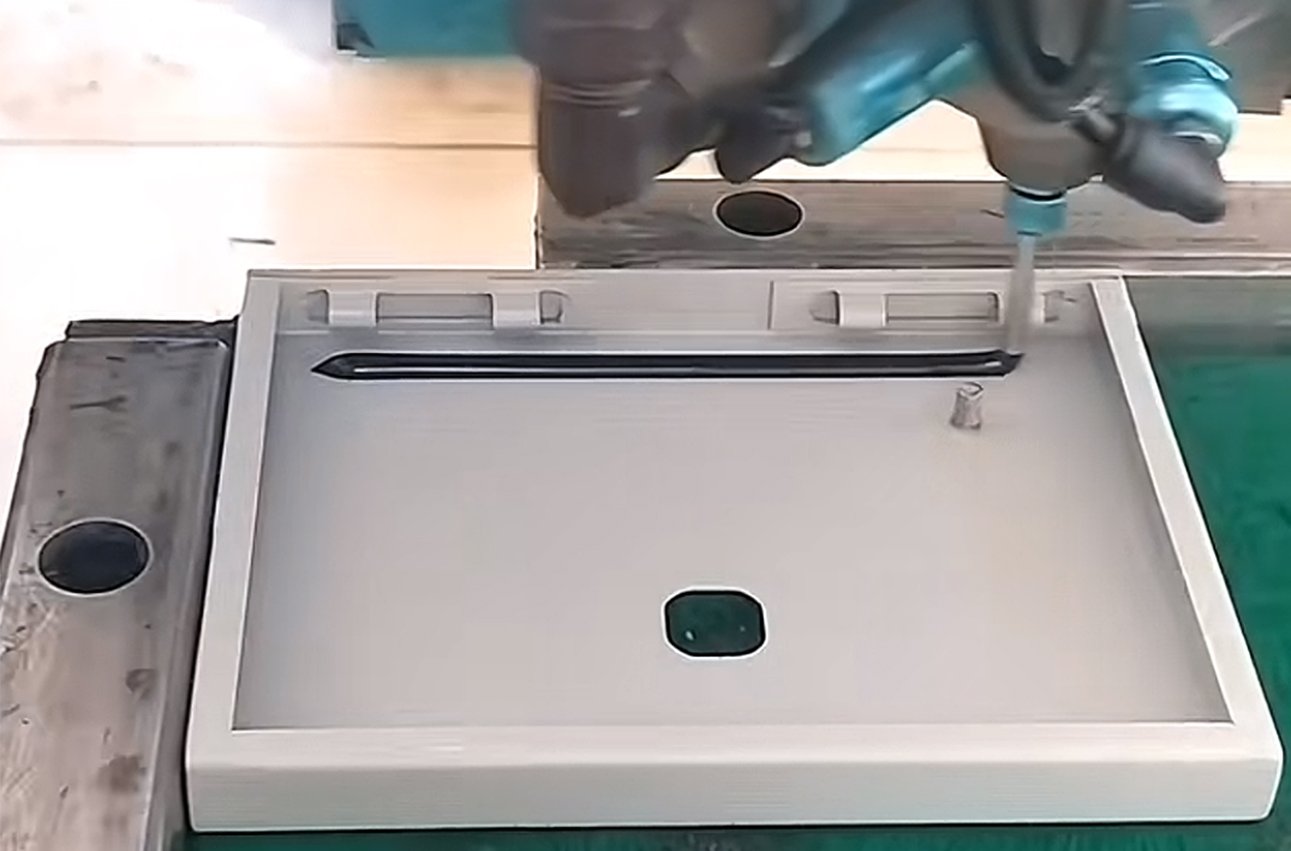

Electrical Enclosure Foaming

High speed and accuracy foaming machines to make rubber ring for the electrical enclosure

Electrical Enclosure Printing

Electrostatic Spray Painting achieve a flawless, durable finish with maximum efficiency. It ensures even coverage on every surface

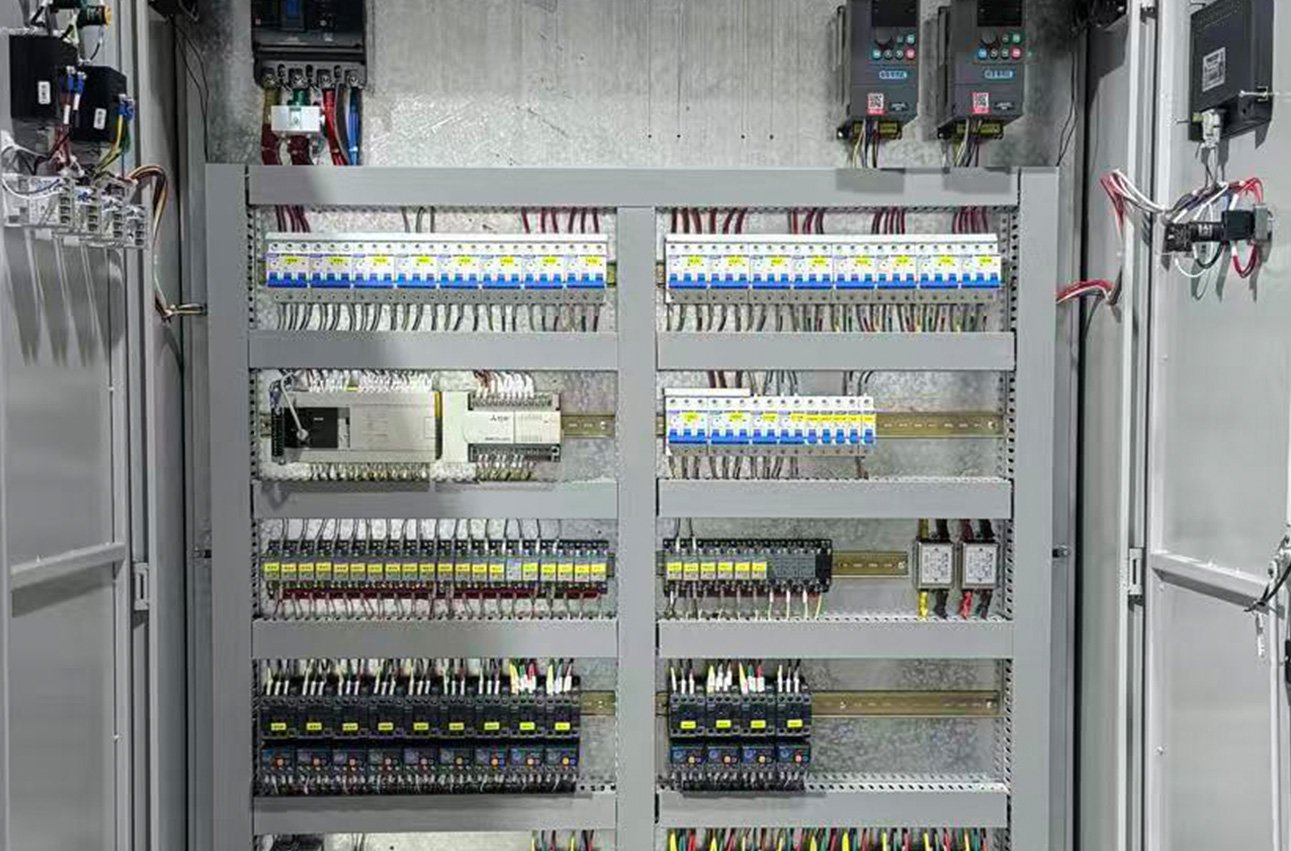

Electrical Enclosure Assembling

Support Electrical system assembling with Branded components