| Application | Indoor |

|---|---|

| Material | Stainless Steel |

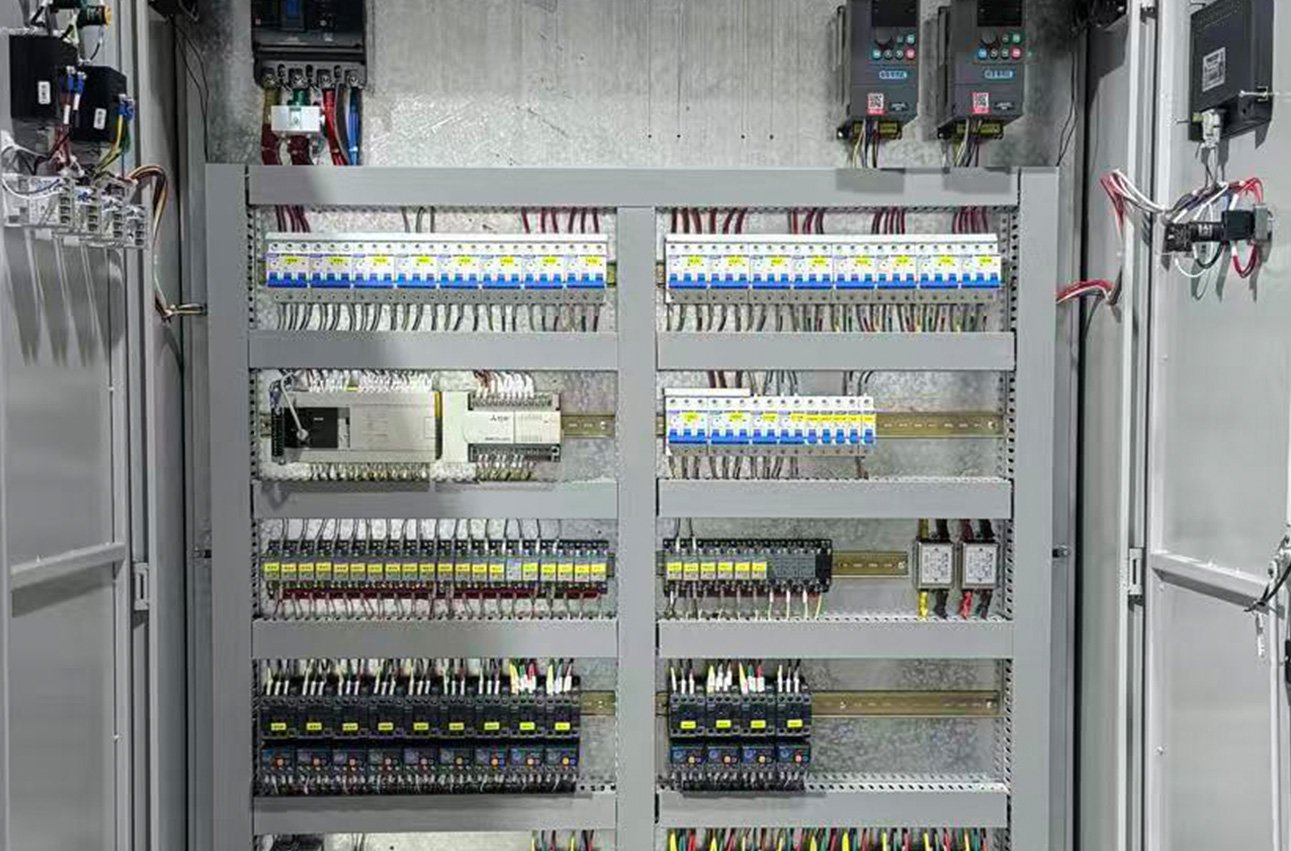

SN-JP Type Comprehensive Distribution Cabinet SS304

Categories All Products, Low Voltage Distribution Box, Power Distribution Box

Tag JP

Features of product

- The JP Type Comprehensive Distribution Cabinet is a standardized device extensively applied in China’s rural grid modernization. It combines the functions of power distribution, metering, protection, and reactive power compensation into an integrated system. Acting as the terminal control unit for low-voltage networks, it is deployed in substations, industrial plants, and residential areas to distribute electricity and ensure line protection and monitoring for a specific zone, such as a village or a factory workshop.

Specification of product

| No. | Order number | W=Width | H=Height | D=Depth | Transformer capacity |

|---|---|---|---|---|---|

| 1 | SNJP657035 | 650 | 700 | 350 | Below 50KVA |

| 2 | SNJP958045 | 950 | 800 | 450 | 50-80KVA |

| 3 | SNJP1058050 | 1050 | 800 | 500 | 100-200KVA |

| 4 | SNJP1259050 | 1250 | 900 | 500 | 160-200KVA |

| 5 | SNJP1359055 | 1350 | 900 | 550 | 250-315KVA |

| 6 | SNJP1559055 | 1550 | 900 | 550 | 400-500KVA |

Don't have the size you need? Please submit the data here

FAQ

What to Consider for Custom Electrical Enclosure Design?

- Structure & Size:Determine size based on installation site, allowing room for operation/maintenance. Use robust materials like cold-rolled steel (1.2-2.0mm) or stainless steel.

- Electrical Performance:Select the appropriate enclosure specifications based on the voltage, current, frequency, and other parameters of the connected equipment.

- Environmental Adaptability:Select the appropriate IP rating based on the installation environment, such as IP54 (dust and water protected) or IP66 (dust-tight and protected against powerful water jets). In chemically corrosive environments, use stainless steel materials or surface zinc plating to extend the enclosure’s service life.

- Heat Dissipation and Ventilation:Incorporate ventilation holes or slots in appropriate areas of the enclosure to prevent excessive internal temperatures.

- Mechanical Structure and Handling:Choose suitable door type (front/side/rear) for easy maintenance. Include lifting hooks for portability. Eliminate sharp edges for operator protection.

How we Manufacture your Custom Electrical Enclosures?

- Confirming the Application Environment:We will communicate with you to understand the specific application scenario of your project. Based on this, we will provide recommendations for suitable materials for the custom electrical enclosure, such as waterproof stainless steel, painted cold-rolled steel, or galvanized steel.

- Confirming Internal Components:We will work with you to confirm the spatial requirements and layout of the internal devices. This allows us to select the appropriate enclosure size and internal configuration to house all components effectively.

- Selecting the Appropriate IP Rating:We will determine the necessary Ingress Protection (IP) rating based on whether the enclosure will be installed indoors or outdoors. The enclosure will then be manufactured to meet the specifications of the required IP standard.

- Choosing a Surface Finish:To meet both functional and aesthetic needs, we offer personalized surface treatment options. These include high-quality color powder coating or an all-over brushed finish for stainless steel. We can also accommodate brand identity requirements by providing custom logo.

How do we provide electrical system services to you?

- Please provide the circuit diagram and application scenario for your project. Our professional engineers will then assess the feasibility of the electrical system design and confirm the assembly plan.

- You can opt for us to assemble your electrical system using branded components (e.g., MCBs, MCCBs, Sockets, Lithium Batteries). Alternatively, provide your Bill of Materials, and we will manage the procurement and assembly.

- The complete system will be assembled by professional engineers and undergo electrical continuity testing to ensure proper circuitry.

SYNNOR

Manufacturing Capacity

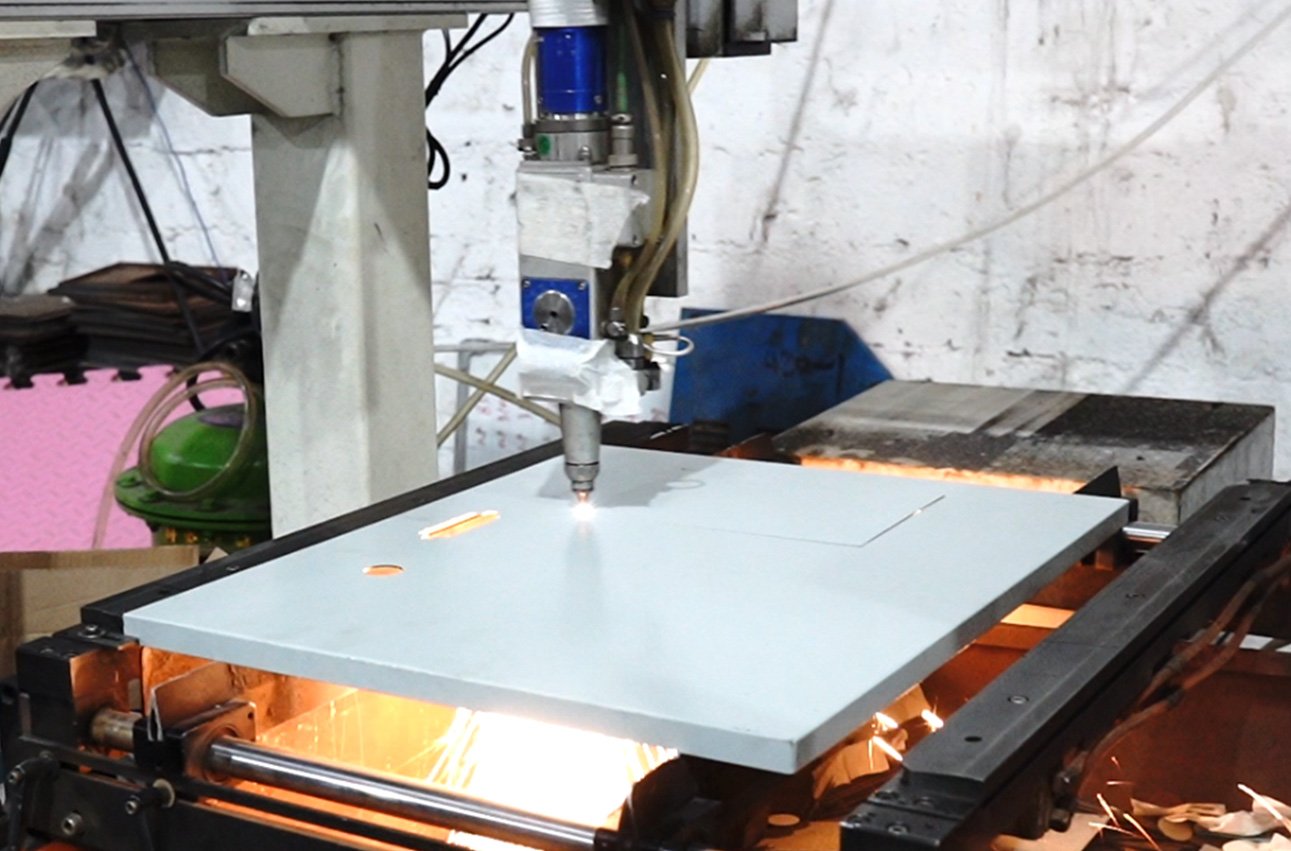

Electrical Enclosure Laser Cutting

±0.05mm precision with smooth, burr-free edges and scratch-free surfaces. High-performance laser cutting, simplified

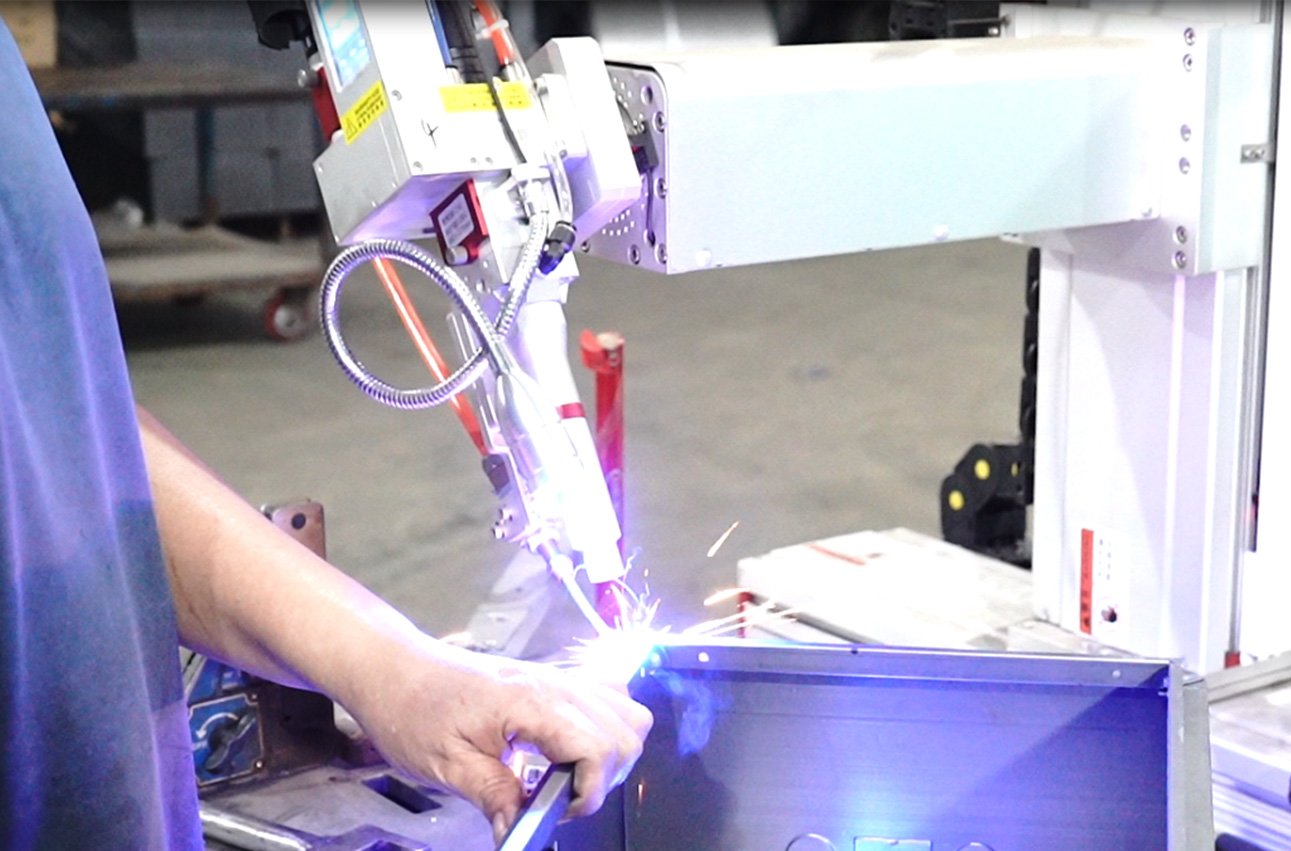

Electrical Enclosure Welding

Argon Arc Welding delivers cleaner, stronger, and higher quality welds and it prevents oxidation for flawless results on metals like stainless steel

Electrical Enclosure Bending

Professional bending machine makes bending accuracy ± 0.5mm, even different designs of junction box

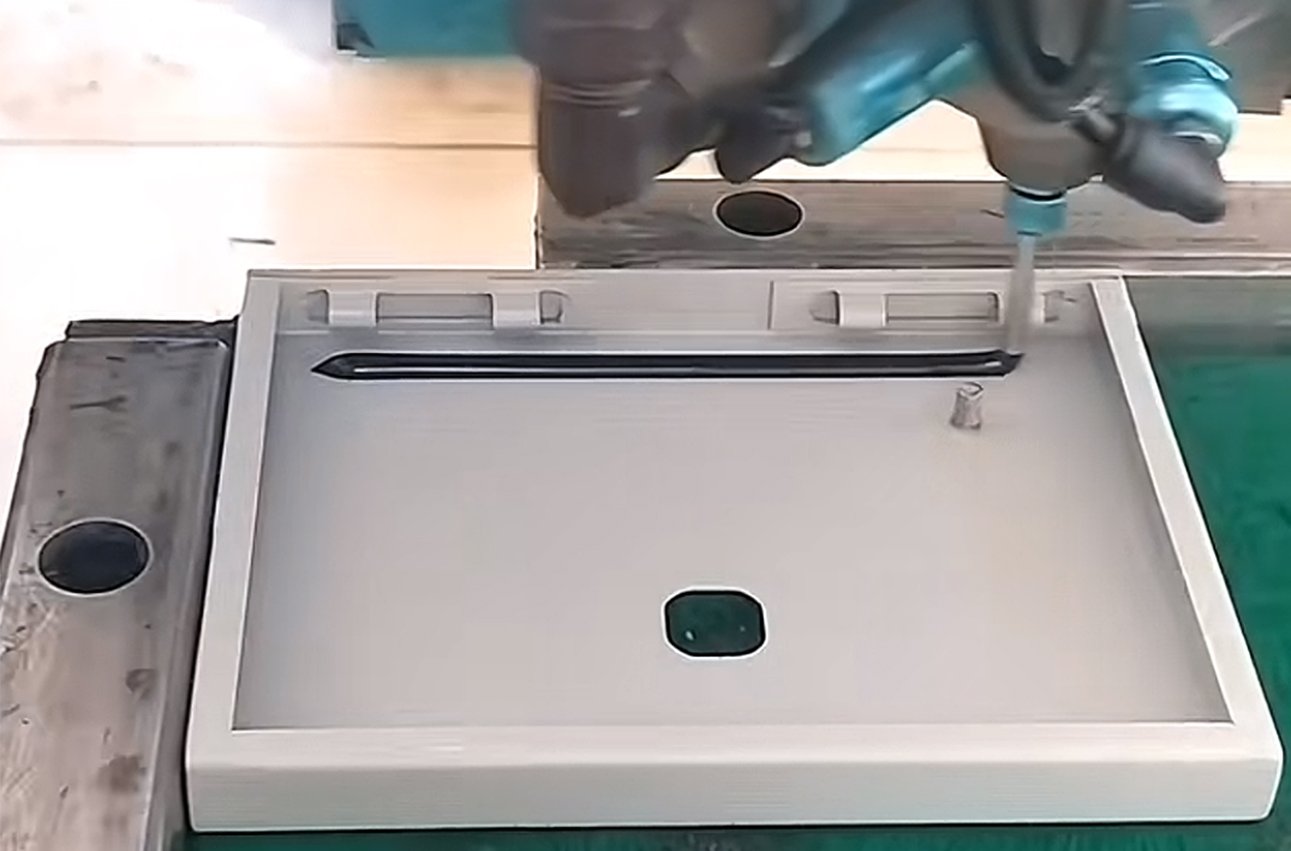

Electrical Enclosure Foaming

High speed and accuracy foaming machines to make rubber ring for the electrical enclosure

Electrical Enclosure Printing

Electrostatic Spray Painting achieve a flawless, durable finish with maximum efficiency. It ensures even coverage on every surface

Electrical Enclosure Assembling

Support Electrical system assembling with Branded components